Jeonju Plant

World’s Largest Scale Plant—Jeonju Plant, an Eco-Friendly CV Production Facility

Status

Further than Driving

Jeonju Factory at a Glance

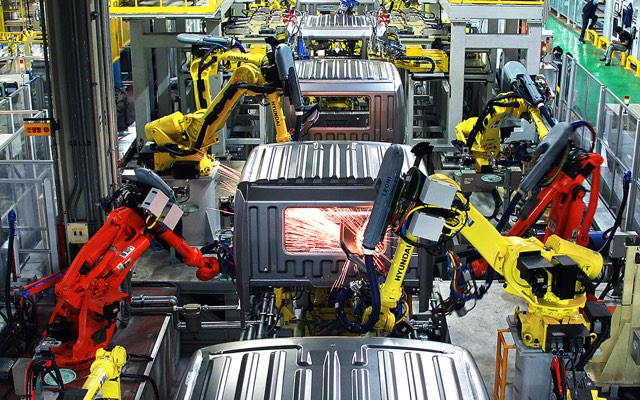

As a highly automated high-tech commercial vehicle manufacturing plant, it is equipped with various cutting-edge production facilities, including robots intended to weld automotive bodies, based on ceaseless innovation and challenges. Designated as a Green Company in 1999 by the Ministry of Environment, it received the same designation in 2003, 2008, and 2013. The company has prioritized communication and cooperation with communities through its eco-friendly efforts.

-

Year of completion

1947

-

No. of employees

1,000

-

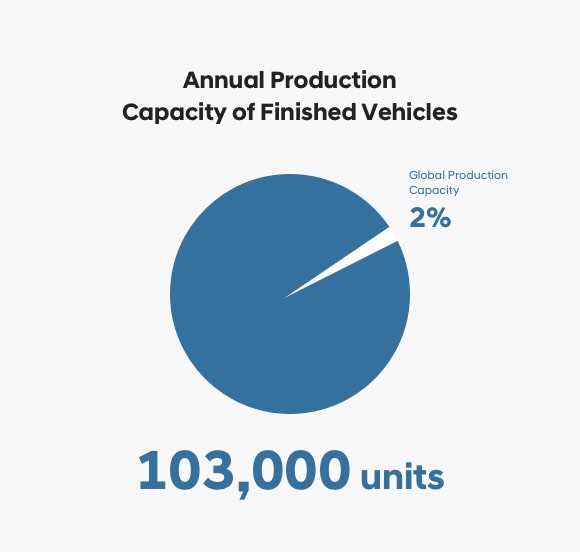

Plant area (103,000 ㎡)

0 times

(larger than a football stadium)

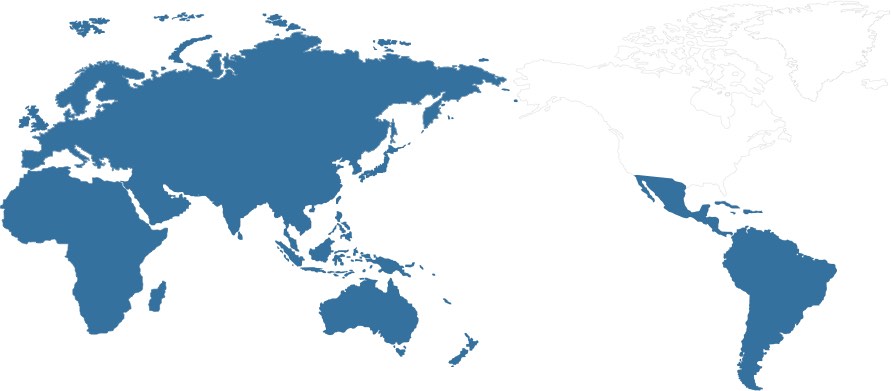

Importing country

0

countries

Vehicle model

0

Models

-

- 8

- Buses

-

- 5

- Trucks

-

- 3

- Special CVs

Features

Independent production systems that cover diverse processes from the development of unique models of large-duty trucks and buses to the manufacture of finished vehicles.

-

World’s Largest CV Production Plant

Except for passenger cars, it can manufacture all kinds of models found in our daily life such as trucks, special commercial vehicles, and medium-duty / large-duty vehicles.

-

Independent Production Systems

Equipped with an R&D center, engine plant, materials plant, proving ground, and dispatch center, it can independently carry out a wide range of business from development to delivery.

-

Eco-Friendly, Green Company

It was designated four times as a Green Company by the Ministry of Environment for its consistent environmental management practices, including devotion to reducing pollutants and saving resources and energy.

Plants

Independent production systems that cover diverse processes from the development of unique models of large-duty trucks and buses to the manufacture of finished vehicles.

Bus Plant 1

It can manufacture high-quality commercial vehicles, thanks to its full lineup systems for medium-duty buses or larger models, as well as its state-of-the-art production facilities.

Bus Plant 2

Vehicle models: Solati, low-floor bus, and County Bare Chassis

-

Truck Plant 1

This key plant manufactures a wide range of medium- / large-duty trucks such as Hyundai Super Truck, Korea’s first and original large-duty truck model, and Xcient, a strategic model exported to Europe. Vehicle models: 2017 HD36L, and Elec City

-

Truck Plant 2

This key plant manufactures a wide range of medium- / large-duty trucks such as Hyundai Super Truck, Korea’s first and original large-duty truck model, and Xcient, a strategic model exported to Europe.

-

Truck Plant 3

This plant is in charge of completing trucks and special commercial vehicles by mounting cargo decks, such as a dump and a trailer, onto the automobile bodies. In particular, it manufactured a vehicle designed to transport livestock when former Honorary President Chung Ju-yung visited North Korea.

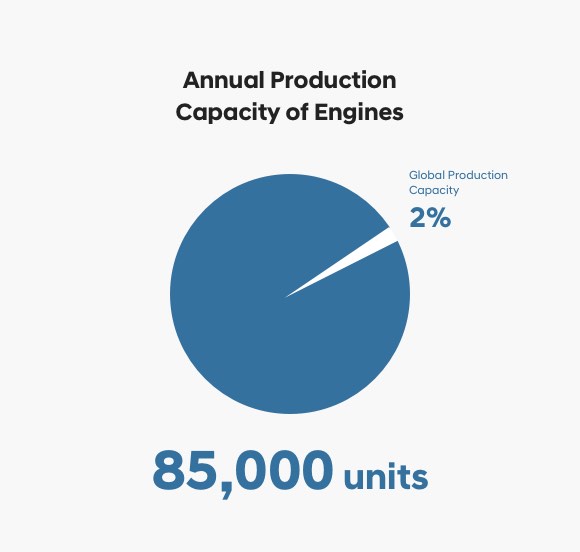

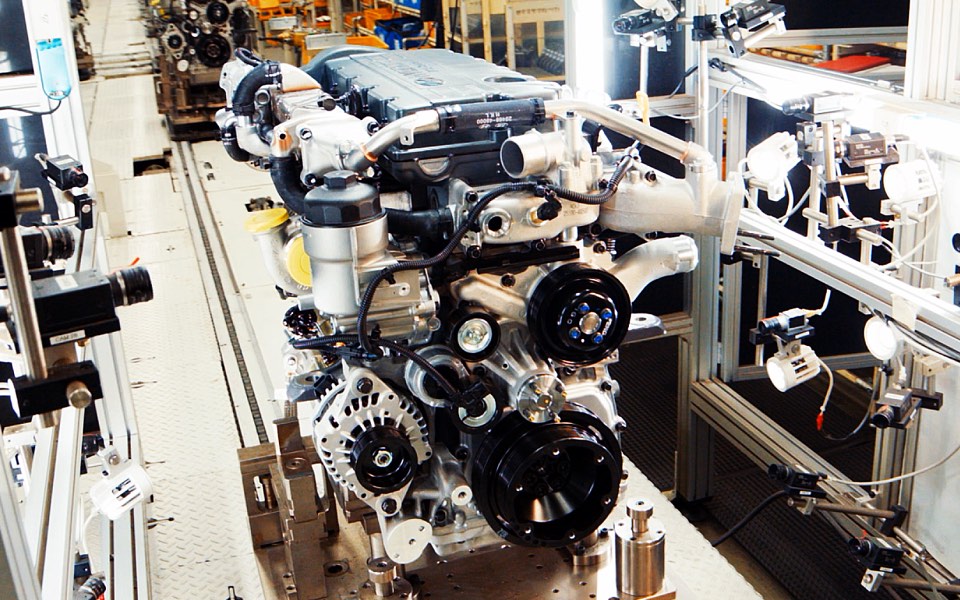

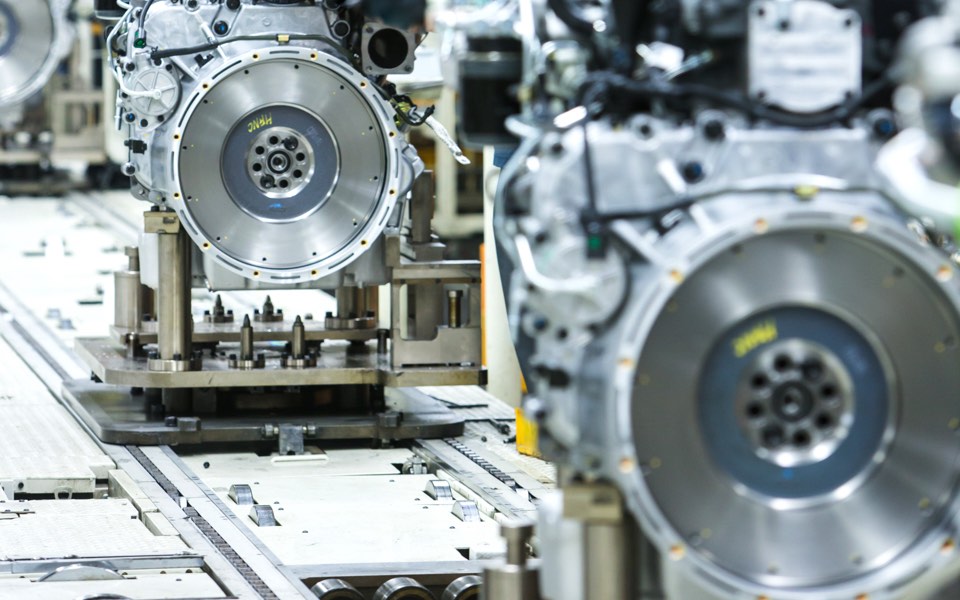

Engine Plant 1

Completed in 1997, it is a full lineup production facility for large-duty engines. Engine models: L/H/Q-CNG/4D3 engines

Engine Plant 2

Completed in 2004, it is an eco-friendly production facility for the self-developed Euro 5 engine. Engine model: F/G engine.

-

Proving Ground

It boasts of a three-kilometer driving test track with diverse environments that all manufactured vehicles can be tested on for their driving performance and mechanical operation. Consequently, it assures customers of its world-class quality control, thus successfully realizing its top priority: customer values.

-

Cargo-Handling Arez

This is a place where finished vehicles from the plant are stored before transport and delivery to customers.

-

Materials Plant

Completed in 1997, it manufactures all sorts of parts and materials essential to the production of CV engines, as well as the completion of independent CV production systems for engines and parts.

Automobile manufacturing process guide

Stand-alone production system that can be developed from the development of large trucks and buses to the production of finished cars.

-

- Stamping

- After the mold is mounted on the press machine that moves up and down, the steel plate is deformed at high pressure to produce frames and body panels that occupy more than 50% of the total weight of the vehicle.

-

- Welding

- The process of making the shape of the car by assembling and receiving the panels requires high precision. The first is to form the body style and secure the safety with a strong combination.

-

- Paint

- Protects materials from corrosion, improves appearance with color, distinguishes it from other vehicles, and improves durability against various climates and environments all over the world.

-

- Assembly

- Built in the body of the vehicle, convenient, etc. after installing the interior and exterior parts, assembling machinery parts such as engine, transmission, axle, complete vehicle with electric parts, wiring and piping work.

-

- Inspection

- Carry out functional inspection including adjustment of wheel alignment of finished vehicle and brake and exhaust gas test. When defect is found, it is corrected and quality control is made before shipment.

Location

Hyundai Motor Jeonju Plant

- Phone

- 82 63 260 5114

- 82 63 260 5125-6 (Tour Info.)

- Address

- 163, Wanjusandan 5-ro Bongdong-eup, Wanju-gun, Jeollabuk-do (Land lot: 800, Yongam-ri, Bongdong-eup, Wanju-gun, Jeollabuk-do)